Clean – Safe – Flexible

Do you care about environmental issues? Are you concerned about climate change? Do you worry about the health of future generations? Would you prefer to keep plastic out of our oceans, chemicals out of our food and water, and dangerous toxicity out of our industrial supply chains?

Whatever your environmental concerns, they likely have a common solution. They will require the development of new technologies. Take climate change, perhaps the most important environmental issue of the twenty-first century. A recent online article on the future of environmental policy, signed by eighteen environmental experts, stated, “We are aware of no quantified climate mitigation scenario in which technological change is not responsible for the vast majority of emissions cuts.”

New technologies. New materials. New manufacturing processes. All are essential to put our planet on a long-term trajectory of environmentally friendly development. And one new breakthrough encompasses all three: compact electron beam technology.

Ebeam technology not only has green benefits—ecological potential that would impress the most passionate environmental activist—but also boasts a powerful business case that is catching the attention of smart CEOs.

Ebeam has the potential to play a critical part in this future. Ebeam has the power to improve our manufacturing footprint, enable the creation of new environmentally friendly materials, and reduce energy usage across the board. And it does all of this while simultaneously achieving the goal of COOs around the world—lower costs.

EBLab 200

EBLab 300

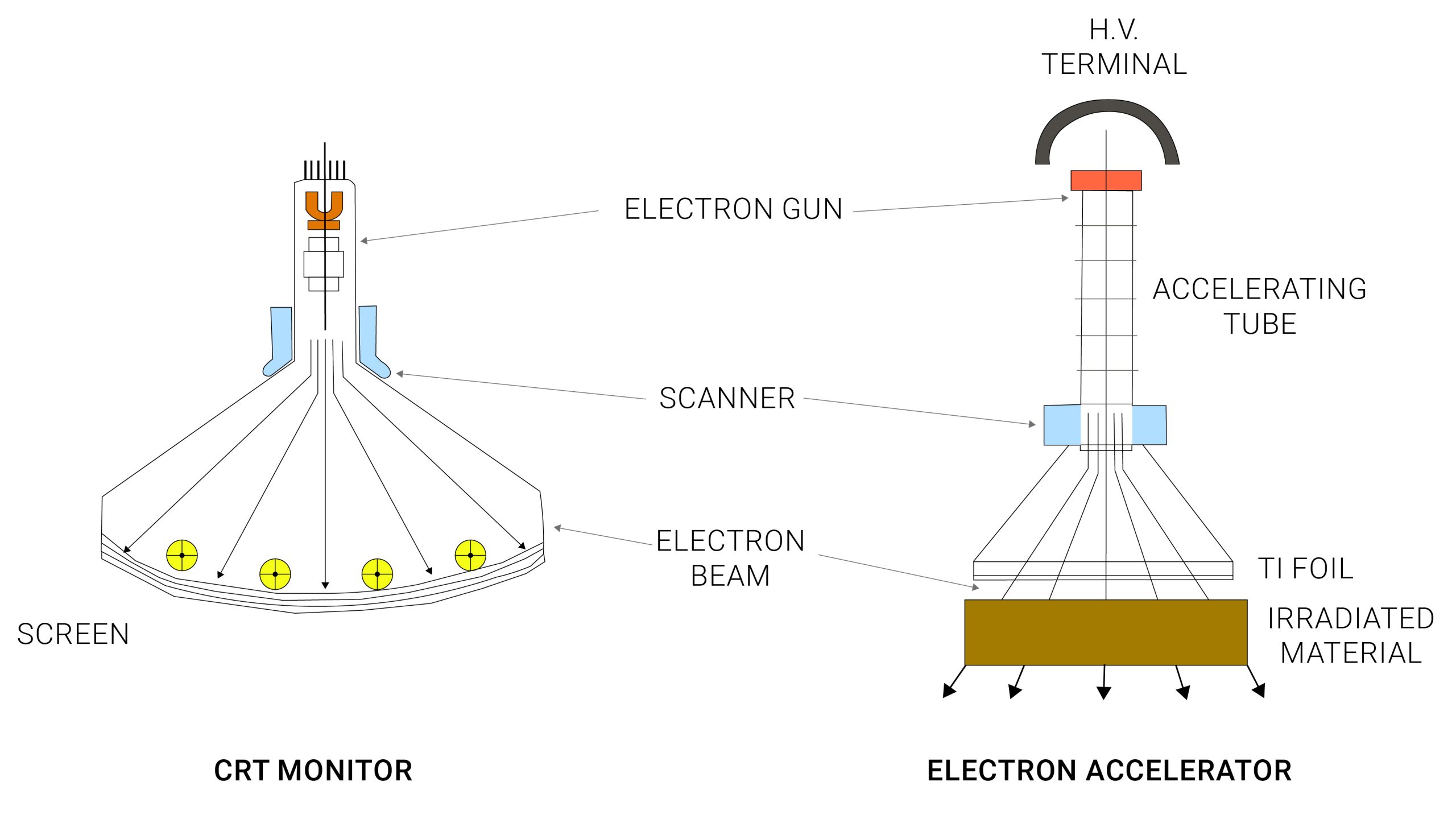

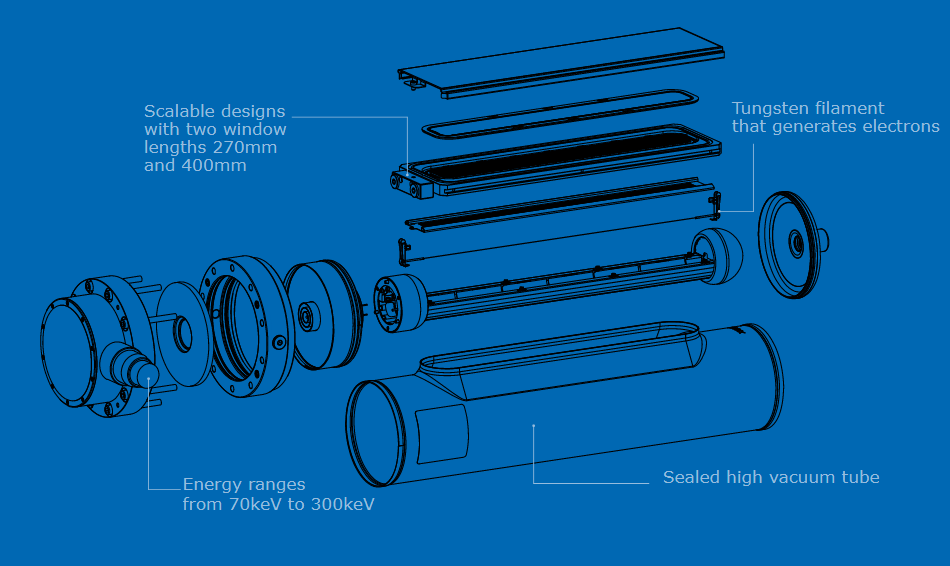

Ebeam Engines

Powerful, robust and reliable. The compact ebeam Engine is made up of a high voltage power supply, a cable, and the ebeam Lamp, an engineering wonder and the heart of the engine. Its sealed design means no vacuum pump and no maintenance. The dynamic, high performance ebeam Lamp is available with a beam energy between 70keV and 300keV. It ushers in a new dimension in ultra-compact engines, allowing for the miniaturization of production lines.

The ebeam Engine was created to easily integrate into your existing production lines. Flexible, precise and efficient, the ebeam Engine is proof that small can be powerful.

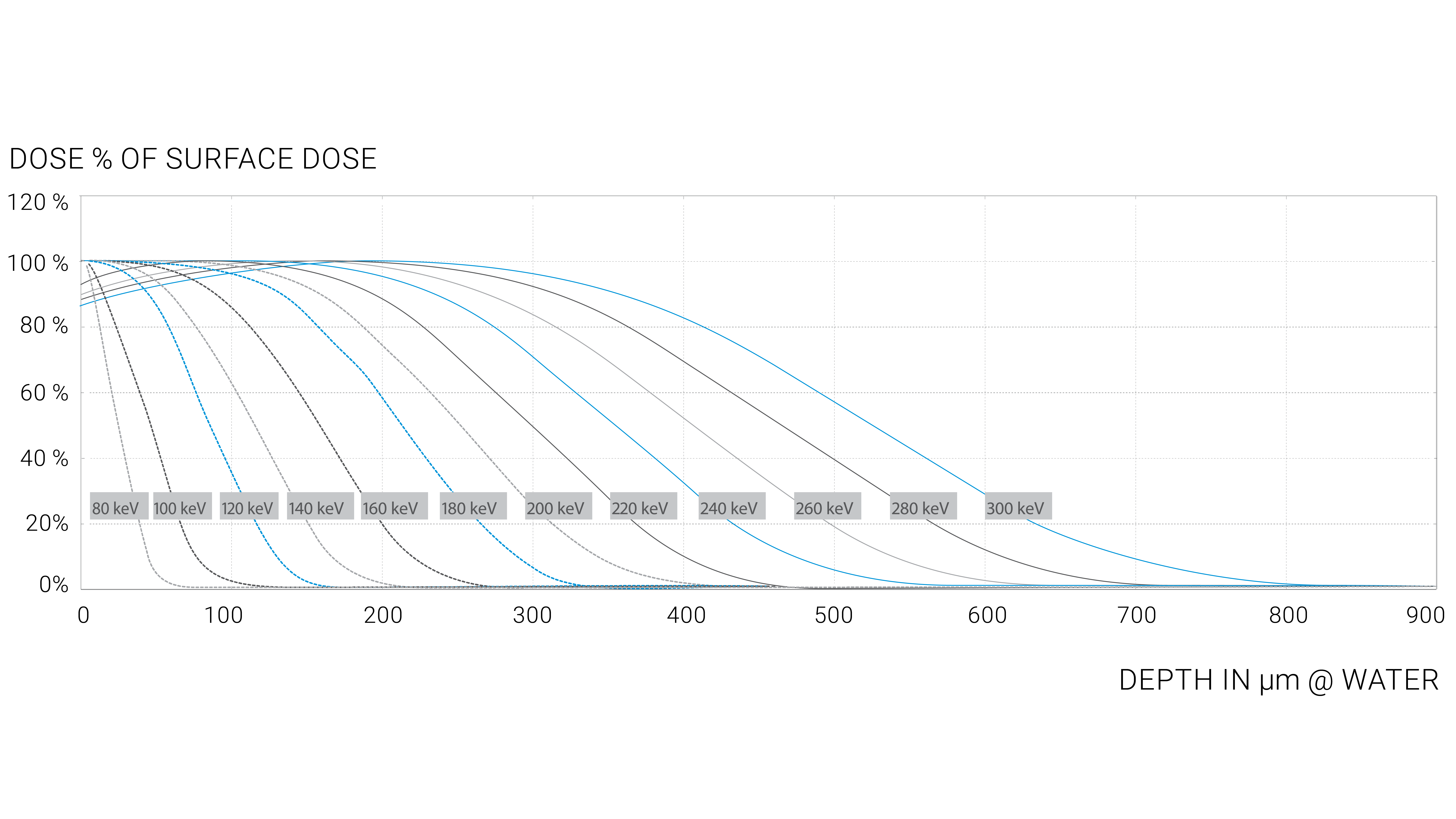

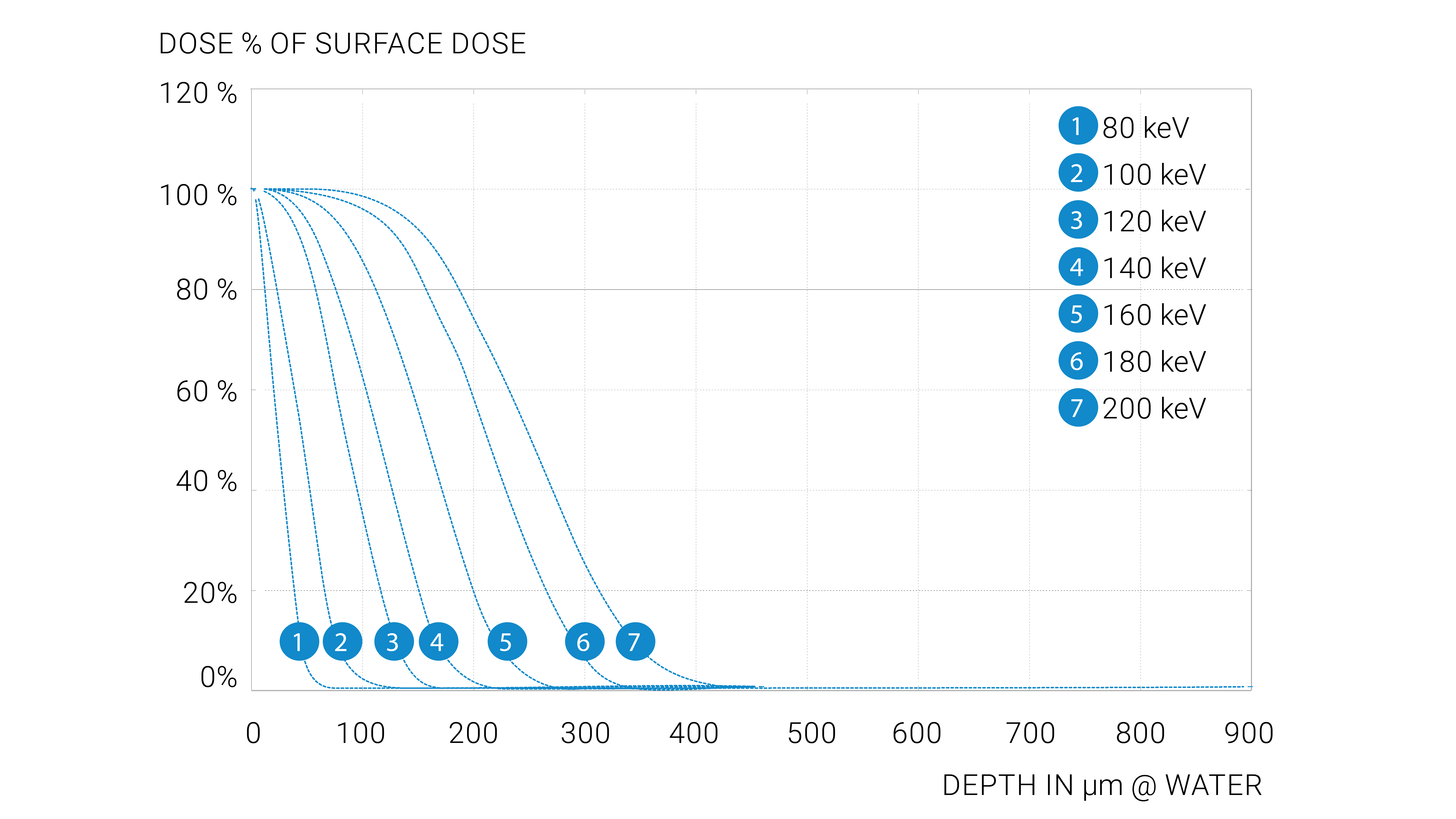

EBLab 300 allows uses for new applications

EBLab 300 enables material treatments from 80 to 300 keV